The Mohs hardness of silicon nitride ceramics is usually above 9, which makes it excellent in wear resistance and scratch resistance. enough to keep its physical and chemical properties stable at extreme high temperatures,the long-term operating temperature can reach 1200°C (short-term 1400°C), and it is suitable for environments with molten metals, glass or high-temperature gases.

MATERIAL : Si3N4

DENSITY : 2.8

COLOR : Black / Blue / White

HRDNESS(Mohs scale) : 9

MAX WORKING TEMPERATURE : 1650

▼Performance characteristic

1. Excellent corrosion resistance : silicon nitride ceramic tube has good corrosion resistance to most acid, alkali, salt and other chemical media, and can maintain stability in harsh chemical environment

2. Excellent high temperature performance : can maintain stable mechanical properties in a high temperature environment of up to 1400℃, suitable for high temperature gas transport and heat exchange equipment

3. High strength and toughness : compared with traditional ceramics, silicon nitride ceramics exhibit higher strength and toughness and can withstand greater impact and load

4. Low friction coefficient and wear : the high hardness (Mohs hardness 8-9) and low friction coefficient of silicon nitride ceramics enable it to maintain a low resistance coefficient during the fluid transmission process, thereby improving the transmission efficiency

5. Good electrical insulation : silicon nitride ceramics are a good electrical insulation material suitable for applications requiring electrical isolation

6. Excellent mechanical properties : silicon nitride ceramics have high yield strength and fracture resistance, and can maintain stability under heavy load

7. Low thermal expansion coefficient : the low thermal expansion coefficient of silicon nitride ceramics can effectively reduce the deformation at high temperature and ensure the stability of the structure

8. High density : through high temperature and pressure sintering process, the density of silicon nitride ceramic tube can reach more than 98%, improve the strength and wear resistance of the material

▼Field of application

1.High-temperature equipment: furnace chamber support rods, sintering kiln roller rods, etc.

2.Electronics industry: Semiconductor wafer transfer rollers, insulating components.

3.Textile machinery: Guide pins, wear-resistant parts, replacing metals to reduce wear.

4.Glass manufacturing: Rollers for glass annealing furnaces, high-temperature resistant and non-stick glass.

5.Laboratory equipment: Corrosion-resistant brackets, precision instrument components.

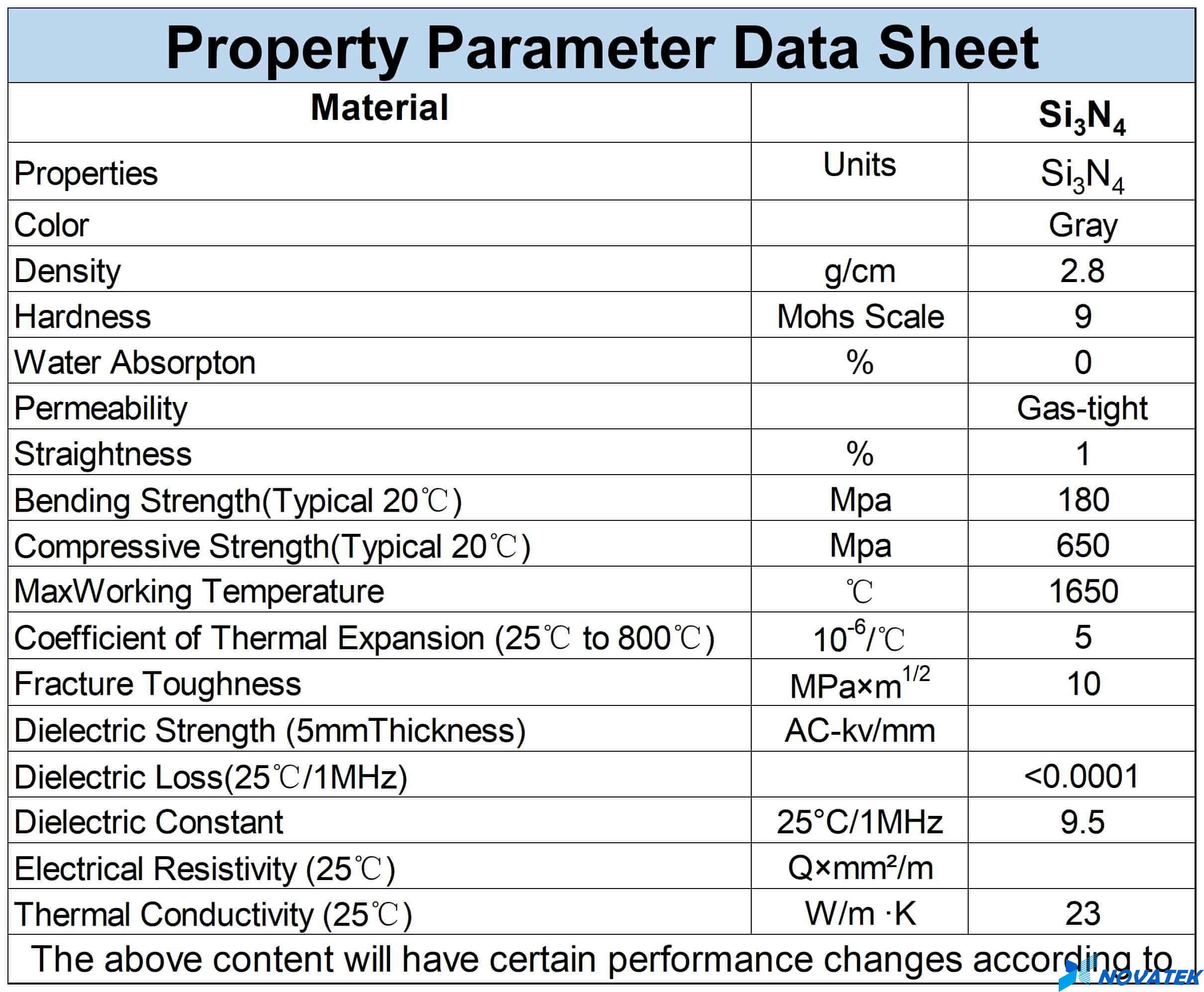

▼Technical Properties of Si3N4 Silicon Nitride Ceramic