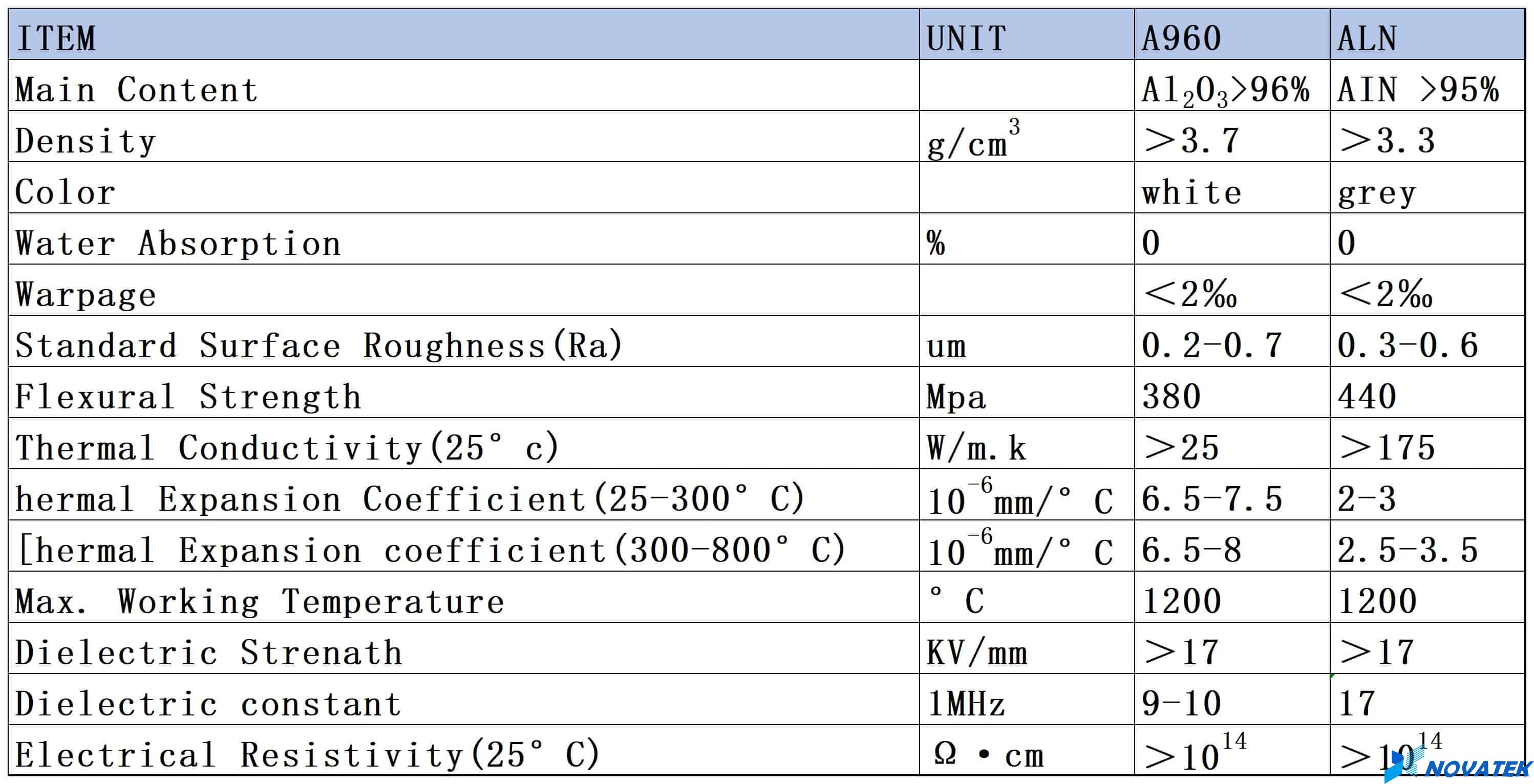

DPCs consist of a ceramic substrate such as Al2O3 (aluminium oxide) and AlN (Aluminum Nitride) serving as an insulating layer, and copper connections to ensure the electrical conductivity at high temperatures. For optimal reliability and performance, the module must demonstrate good properties in relation to heat dissipation to the heat sink and endurance against thermal cycling and power cycling.

MATERIAL

Al2O3 / AlNDENSITY

3.30-3.70 g/cm3COLOR

white / greyDirect Plated Copper (DPC) is the newest development in the field of Ceramic Substrate PCBs and using this method can result in copper thickness' ranging from 10um (≈ 1/3oz) to 140um (4oz). With DPC track printing and etching is then performed with the thin Copper allowing for very fine tracks and reduced undercutting.

DPC Ceramic Substrate is the long-proven standard for power electronic modules in industrial, home-appliances and automotive applications. Unipretec ceramic substrates DPC have an excellent performance/cost efficiency ratio. The great heat conductivity of Al2O3 (25 W/mK) and AlN (175 W/mK) as well as the high heat capacity make the substrate irreplaceable in power electronics. The thick copper foils offer extremely good electrical and thermal conductivity and form an outstanding base for the soldering and wire bonding processes.

| ✔High Mechanical Strength | ✔Good Thermal Conductivity |

| ✔ Excellent Electrical Insulation | ✔ Outstanding Chemical Stability |

| ✔ Extremely High Service Temperature | ✔ Small Thermal Expansion Coefficient |